Generator Performance Optimization & ComAp Control System Upgrade at Laffan Resin Factory

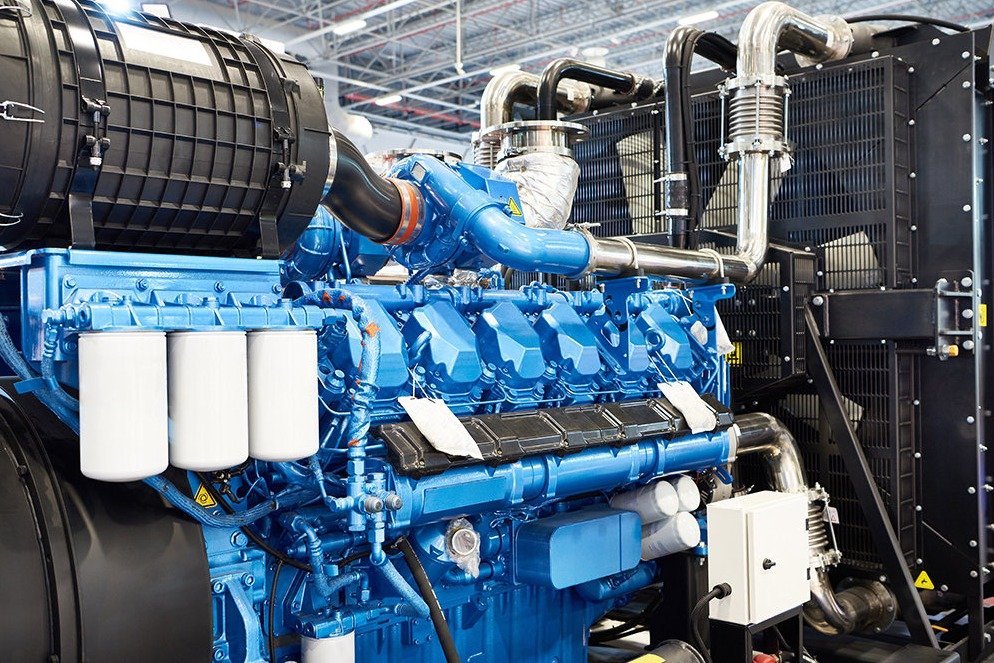

This project focuses on enhancing generator performance and implementing a new control system to maximize power output and operational reliability. The scope includes fine-tuning generators to achieve a target output of 187kW, supplying and installing a new ComAp controller with fiber optic communication, and conducting comprehensive load bank testing to validate performance under controlled conditions.

1. Generator Performance Tuning: Configuration and adjustment to maximize mechanical/electrical output, setting maximum output to 187kW per generator condition

2. Control System Supply & Installation: Supply and installation of ComAp InteliGen BaseBox controller with manufacturer warranty

3. Communication Infrastructure: Supply and installation of fiber optic cables (10-15M) from main controller to Generator #12

4. System Programming & Testing: Programming/configuration of controller and load bank testing of all generators

• Optimized Generator Performance: Generators tuned to deliver maximum reliable output of 187kW

• Modernized Control System: New ComAp controller installed and operational with secure fiber optic communication

• Validated Performance: Load bank testing confirms generators meet specified performance standards

• Enhanced System Reliability: Improved control and monitoring capabilities for Generator #12 operations