Generator Performance Optimization and Rectification Project at Laffan Resin Factory

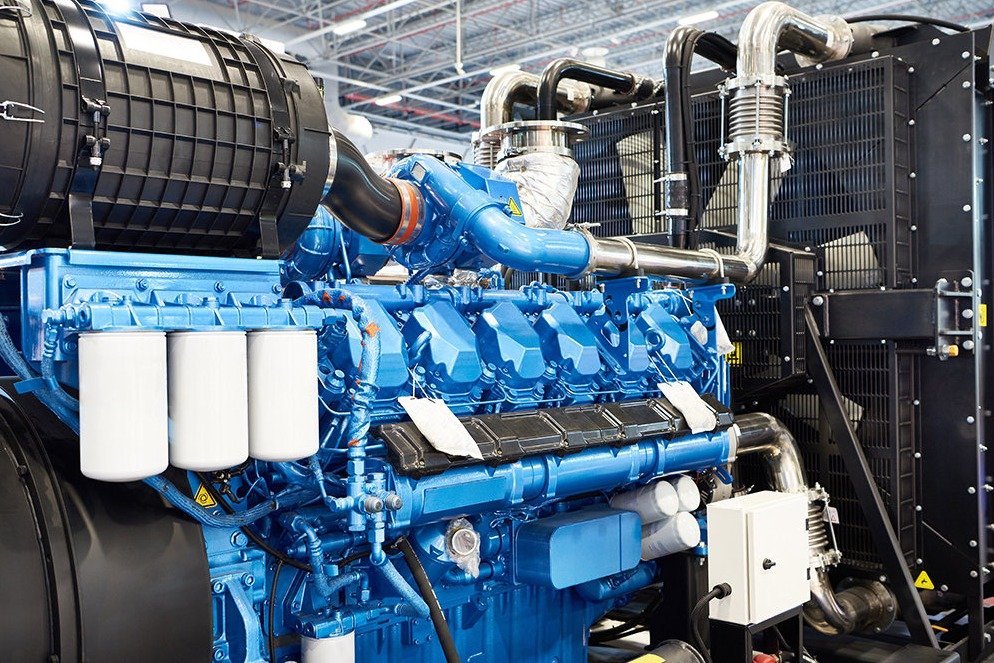

This project provides comprehensive engineering services to diagnose, analyze, and resolve critical performance issues with multiple generators at Laffan Resin Factory. The scope includes rectification of a ComAp control panel, optimization of generator power output, investigation of load fluctuation problems, and analysis of excessive oil consumption across specific generator units to improve reliability and operational efficiency.

1. ComAp Controller Rectification: Diagnosis and repair of the InteliGen NTC BaseBox controller on Generator #12

2. Performance Optimization Analysis: Load flow study on one selected unit to maximize mechanical/electrical output

3. Load Fluctuation Investigation: Case study and identification of hunting issues on Generator #05 pre/post synchronization

4. Oil Consumption Analysis: Investigation of excess oil loss on Generators #02 and #09

5. Technical Recommendations: Comprehensive reporting with proposed solutions for all identified issues

• Restored Control System: Fully operational ComAp controller on Generator #12

• Optimized Power Output: Recommendations to achieve maximum generator performance capacity

• Stable Operation: Solutions to resolve load fluctuation and hunting issues on Generator #05

• Reduced Oil Consumption: Identification of root causes and corrective actions for oil leakage problems

• Comprehensive Improvement Plan: Detailed technical recommendations for enhancing overall generator reliability and efficiency